How To Clean Underneath C Stick Pcb

What's Best for Cleaning Under Low Clearance SMT Components?

Contamination is 1 of the primary drivers of field failures in electronics today. Corrosion and electrochemical migration ("ECM") is directly acquired by residues left on PCBs. Contamination-related failures are pervasive and have been observed on batteries, LCDs, PCBAs, wiring, switches, nether coatings, over coatings, etc. The problem is expected to go worse as continued reductions in pitch between conductors makes time to come packaging more than susceptible. Contaminants are concentrated under these depression standoff devices.

This didn't used to exist a problem. Until the 1970s, almost all electronics were congenital from individual components, with the labor-intensive assembly of thousands of carve up diodes and transistors. The miniaturization demanded past the space race led to the first computer chips called "plated through-pigsty" circuit lath designs. The defining concrete feature of a through-hole PCB are the "legs" that extend from the components. These chips accept a high "stand-off" from the lath which makes it easy to clean the rosin flux residues that migrated under the components.

The belatedly 1980s saw the evolution to the first SMT "surface mountain technology" components. Shorter legs and tighter stand-offs enabled more than chips per-square centimeter, making the resulting tools "smarter." Many fleck designs, such as the popular QFP format, had 200+ electric connections which made the chips extremely powerful.

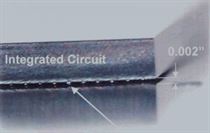

But past the turn of the century, ball grid array ("BGA") components were becoming commonplace. BGA components jammed fifty-fifty more than transistors into the smallest possible package. Each chip supported thousands of tiny solder connections (hidden underneath the flake) which make them extremely rugged, even in harsh environments. BGA designs have stand-offs measured in microns. The increased employ of leadless and bottom termination components (QFN, land grid array, etc.), multi-chip modules and other advanced component designs results in a reduction in standoff meridian which reduces the efficiency of cleaning.

These dense designs are difficult to make clean, and cleaning is absolutely disquisitional to longevity and performance. Specifically, estrus from the component accelerates the reactions formed with salt complexes which can so crusade corrosion or dendrite growth on the PCBs, causing the PCB to fail. Dense PCB designs run hot, so corrosion that might take years in a benign role environment tin can happen in just days in a hot, humid environment.

For all-time cleaning results, PCB fabricators should seek out cleaning fluids that are very pure and uncontaminated, with a high Kb value, with depression surface tension and low viscosity. Water simply will not become under these tight-plumbing fixtures components, and if somehow it does go under the chip it will rarely ever comes back out. For best results, consider the Heavy Duty Flux Remover — SuprClean™ (#MCC-SPR). Other skilful options are the No-Make clean Flux Remover — VeriClean™ (#MCC-DC1) and the General Purpose Flux Remover (#MCC-FRC).

BGA components like this i link their electric connections with thousands of tiny solder joint hidden beneath the component. These tin can be very difficult to clean with traditional liquids

How To Clean Underneath C Stick Pcb,

Source: https://www.microcare.com/en-US/Resources/Resource-Center/FAQs/What-s-Best-for-Cleaning-Under-Low-Clearance-SMT-C

Posted by: cheungscalwat.blogspot.com

0 Response to "How To Clean Underneath C Stick Pcb"

Post a Comment